Ngokophando kunye nohlalutyo, ukubola yenye yezinto ezibalulekileyo ezibangela umonakalo kwiivalve zebhabhathane.Ngenxa yokuba umngxuma ongaphakathi unxibelelana nendawo, wonakele kakhulu.Emva kwe-corrosion, ububanzi be-valve buba buncinci kwaye ukunyuka kwe-flow resistance kuyanda, okuchaphazela ukuhanjiswa kwe-medium.Umphezulu womzimba wevalvu ufakwa ikakhulu emhlabeni okanye phantsi komhlaba.Umphezulu udibana nomoya kwaye nomoya ufumile, ngoko ke kuthanda ukugqwala.Isitulo sevalve sigqunywe ngokupheleleyo apho umngxuma ongaphakathi udibana nendawo.Ke ngoko, unyango lokugquma komphezulu womzimba wevalve kunye nepleyiti yevalve yeyona ndlela ingabizi kakhulu yokukhusela ngokuchasene nokubola kwimeko yangaphandle.

1. Indima yomphezulu wevalve yebhabhathane

01. Ukuchongwa kwempahla yomzimba yevalvu

Umbala womaleko womphezulu usetyenziswa kwiindawo ezingalungiswanga zomzimba wevalvu kunye nebhonethi.Ngokumakishwa kombala, sinokukhawuleza ukugqiba izinto eziphathekayo zevalve kwaye siqonde ngcono iimpawu zayo.

| Isixhobo soMzimba weValve | Umbala wepeyinti | Isixhobo soMzimba weValve | Umbala wepeyinti |

| Jula i-ayini | Mnyama | Intsimbi yentsimbi | Luhlaza |

| Intsimbi eyenziweyo | Mnyama | WCB | Ngwevu |

02. Impembelelo yokukhusela

Emva kokuba umphezulu womzimba wevalve uqatywe ngepeyinti, umphezulu womzimba wevalvu ubekwe wodwa kwindawo engqongileyo.Esi siphumo sokukhusela sinokubizwa ngokuba yimpembelelo yokukhusela.Nangona kunjalo, kufuneka kucaciswe ukuba ipeyinti encinci yepeyinti ayikwazi ukubonelela ngempembelelo yokukhusela ngokupheleleyo.Ngenxa yokuba iipolymers zinezinga elithile lokuphefumula, xa iingubo zincinci kakhulu, iipores zesakhiwo zivumela amanzi kunye ne-oksijini iamolekyu ukuba idlule ngokukhululekile.Iivalvu zokutywina ezithambileyo zineemfuno ezingqongqo kubunzima be-epoxy resin coating kumphezulu.Ukuze kuphuculwe ukungahambi kakuhle kwengubo, i-anti-corrosion coatings kufuneka isebenzise izinto ezenza ifilimu ezinomoya ophantsi kunye nezizaliso eziqinileyo ezineempawu eziphezulu zokukhusela.Ngelo xesha, inani leengubo zokugqoka kufuneka linyuswe ukwenzela ukuba i-coating ifike kubunzima obuthile kwaye i-dense kwaye ingabikho.

03.Ukuthintela umhlwa

Amacandelo angaphakathi epeyinti asabela ngesinyithi ukuze adlulise umphezulu wesinyithi okanye enze izinto ezikhuselayo zokuphucula umphumo wokukhusela wokugquma.Kwiivalve ezineemfuno ezizodwa, kufuneka ubeke ingqalelo ekubunjweni kwepeyinti ukuze ugweme imiphumo emibi kakhulu.Ukongeza, iivalvu zentsimbi ezisetyenziswe kwimibhobho yeoli zinokusebenza njenge-organic corrosion inhibitors ngenxa yeemveliso zokonakala ezenziwe phantsi kwesenzo se-oyile ethile kunye nesenzo sokomisa iisepha zentsimbi.

04. Ukhuseleko lwe-electrochemical

Xa i-dielectric penetrating coating idibana nomphezulu wesinyithi, i-electrochemical corrosion phantsi kwefilimu iya kwenza.Izinyithi ezinomsebenzi ophezulu kunentsimbi zisetyenziselwa ukuzalisa kwiingubo, ezifana ne-zinc.Kuya kudlala indima yokukhusela njenge-anode yombingelelo, kunye nemveliso ye-zinc i-zinc-based based zinc chloride kunye ne-zinc carbonate, eya kugcwalisa izithuba kwifilimu kwaye yenze ifilimu ibe nzima, inciphisa kakhulu i-corrosion kunye nokwandisa ubomi benkonzo. ivalve.

2. Iingubo ezisetyenziswa ngokuqhelekileyo kwiivalve zetsimbi

Iindlela zokunyanga umphezulu wevalvu ikakhulu zibandakanya ukugquma kwepeyinti, igalvanizing kunye nomgubo wokugquma.Ixesha lokukhusela lepeyinti lifutshane kwaye alikwazi ukusetyenziswa phantsi kweemeko zokusebenza ixesha elide.Inkqubo yokufaka igalvanizing isetyenziswa kakhulu kwimibhobho.Zombini i-galvanizing eshushu-dip kunye ne-electro-galvanizing zisetyenziswa.Inkqubo inzima.Unyango lwangaphambili lusebenzisa iinkqubo zokuchola kunye ne-phosphating.Kuya kubakho i-asidi kunye neentsalela zealkali kumphezulu we-workpiece, ukushiya ukubola Ingozi efihliweyo yenza ukuba umaleko owenziwe ngamazi kube lula ukuwa.Ukuxhatshazwa kwe-corrosion yensimbi ye-galvanized yi-3 ukuya kwi-5 iminyaka.I-powder coating esetyenziswa kwiivalvu zethu zeZhongfa ineempawu zokugquma okutyebileyo, ukuxhathisa ukubola, ukuxhathisa ukhukuliseko, njl.njl., ezinokuhlangabezana neemfuno zeevalvu phantsi kweemeko zokusetyenziswa kwenkqubo yamanzi.

01. I-valve yomzimba we-epoxy resin yokugqoka

Inezi mpawu zilandelayo:

·Ukumelana nokubola: Imivalo yentsimbi ene-epoxy resin-coated inokumelana ne-corrosion elungileyo, kwaye amandla okubopha ngekhonkrithi ancitshiswe kakhulu.Zifanelekile kwiimeko zoshishino kwiindawo ezimanzi okanye imidiya ephazamisayo.

·Ukunamathela olomeleleyo: Ubukho bamaqela epolar hydroxyl kunye neebhondi ze-ether ezikwi-epoxy resin molecular chain kuyenza incamathele kakhulu kwizinto ezahlukeneyo.I-shrinkage ye-epoxy resin xa iphiliswa iphantsi, uxinzelelo lwangaphakathi olwenziweyo luncinci, kunye nokukhusela indawo yokukhusela akulula ukuwa kunye nokuhluleka.

·Iimpawu zombane: Inkqubo ye-epoxy resin enyangisiweyo yinto egqwesileyo yokugquma eneempawu eziphezulu ze-dielectric, ukumelana nokuvuza komphezulu, kunye nokumelana ne-arc.

·Ukumelana nokuMngunda: Inkqubo enyangisiweyo ye-epoxy resin iyaxhathisa kuninzi lokungunda kwaye ingasetyenziswa kwiimeko ezirhabaxa zetropikhi.

02. Imathiriyeli yepleyiti yenayiloni yevalve

Amaphepha enayiloni amelana nomhlwa ngokugqithisileyo kwaye asetyenziswe ngempumelelo kwizicelo ezininzi ezinje ngamanzi, udaka, ukutya kunye nokukhutshwa kwetyuwa emanzini olwandle.

·Ukwenziwa kwangaphandle: Ipleyiti yenaliti yenayiloni inokuluphumelela uvavanyo lwesitshizi setyuwa.Ayizange ixobuke emva kokuntywiliselwa emanzini olwandle iminyaka engaphezu kwama-25, ngoko akukho mhlwa kwiindawo zentsimbi.

·Ukumelana nokunxiba: Ukumelana kakuhle kakhulu nokunxiba.

·Ukuchasana nempembelelo: Akukho zimpawu zokuxobuka phantsi kweempembelelo ezinamandla.

3. Inkqubo yokutshiza

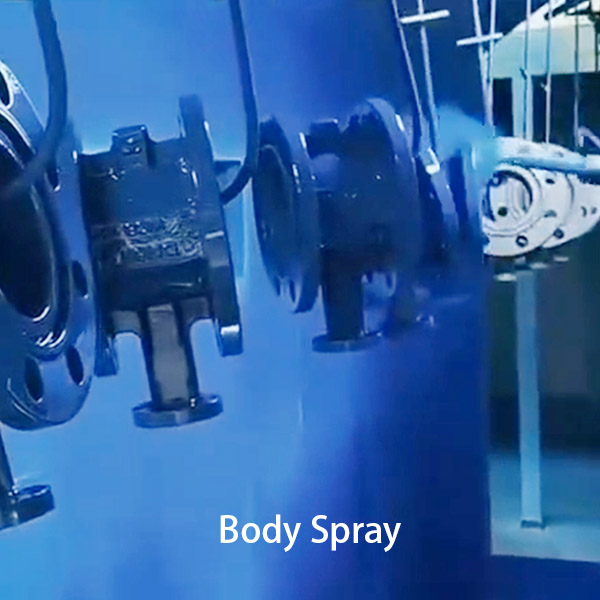

Inkqubo yokutshiza kukulungiswa kwangaphambi kokusebenza → ukususwa kothuli → ukufudumeza kwangaphambili → ukutshiza (i-primer - trimming - topcoat) → ukuqinisa → ukupholisa.

Ukutshiza Ukutshiza ikakhulu kusebenzisa ukutshiza nge-electrostatic.Ngokuhambelana nobukhulu be-workpiece, ukutshiza kwe-electrostatic kunokohlulwa kumgca wemveliso wokutshiza we-electrostatic kunye neyunithi yokutshiza yomgubo we-electrostatic.Ezi nkqubo zimbini ziyafana, kwaye umahluko ophambili yindlela yokuguqula i-workpiece.Umgca wemveliso wokutshiza usebenzisa ikhonkco losasazo losasazo oluzenzekelayo, ngelixa iyunithi yokutshiza iphakanyiswa ngesandla.Ubunzima bengubo bulawulwa kwi-250-300.Ukuba ubukhulu bungaphantsi kwe-150 μm, ukusebenza kokukhusela kuya kuncitshiswa.Ukuba ubukhulu bukhulu ngaphezu kwe-500 μm, i-adhesion yokugqoka iya kuncipha, ukuchasana kwempembelelo kuya kuncipha, kwaye ukusetyenziswa kwepowder kuya kwanda.