Ngokophando nohlalutyo, ukugqwala yenye yezinto ezibalulekileyo ezibangela umonakalo kwiivalvu zeebhabhathane. Ngenxa yokuba umngxuma wangaphakathi udibana nomthombo, uyagqwala kakhulu. Emva kokugqwala, ububanzi bevalvu buba mncinci kwaye ukumelana nokuhamba kwamanzi kuyanda, nto leyo echaphazela ukudluliselwa komthombo.umphezulu womzimba wevalvuIfakwa kakhulu emhlabeni okanye phantsi komhlaba. Umphezulu udibana nomoya kwaye umoya umanzi, ngoko ke unokuba nomhlwa. Isihlalo sevalvu sigqunywe ngokupheleleyo apho umngxuma wangaphakathi udibana nomthombo. Ke ngoko, unyango lomgangatho womzimba wevalvu kunye nepleyiti yevalvu yeyona ndlela yokukhusela engabizi kakhulu nxamnye nokugqwala kwindawo engaphandle.

1. Indima yokugquma umphezulu wevalvu yebhabhathane

01. Ukuchongwa kwezinto zomzimba wevalvu

Umbala womaleko womphezulu usetyenziswa kwiindawo ezingafakwanga matshini zomzimba wevalvu kunye nebhonethi. Ngale mibala, sinokufumanisa ngokukhawuleza izinto zomzimba wevalvu size siqonde ngcono iimpawu zayo.

| Izinto zoMzimba weValve | Umbala wepeyinti | Izinto zoMzimba weValve | Umbala wepeyinti |

| Jula i-ayini | Mnyama | Intsimbi ethambileyo | Luhlaza |

| Intsimbi Eyenziweyo | Mnyama | I-WCB | Ngwevu |

02. Isiphumo sokukhusela

Emva kokuba umphezulu womzimba wevalvu ugqunywe ngepeyinti, umphezulu womzimba wevalvu uhlukaniswe ngokwendalo. Esi siphumo sokukhusela singabizwa ngokuba sisiphumo sokukhusela. Nangona kunjalo, kufuneka kuphawulwe ukuba umaleko omncinci wepeyinti awunakubonelela ngesiphumo sokukhusela ngokupheleleyo. Ngenxa yokuba iipolymers zinomlinganiselo othile wokuphefumla, xa isiciko sincinci kakhulu, iimbobo zesakhiwo zivumela amanzi kunye neemolekyuli zeoksijini ukuba zidlule ngokukhululekileyo. Iivalvu ezitywinayo zineemfuno ezingqongqo kubukhulu besiciko se-epoxy resin kumphezulu. Ukuze kuphuculwe ukungangeni kwesiciko, isiciko esichasene nokugqwala kufuneka sisebenzise izinto ezenza ifilimu ezinomoya ophantsi kunye nezizalisi eziqinileyo ezineempawu zokukhusela eziphezulu. Kwangaxeshanye, inani leengqimba zesiciko kufuneka landiswe ukuze isiciko sifikelele kubukhulu obuthile kwaye sibe sikhulu kwaye singabi namingxuma.

03. Ukuthintela ukugqwala

Izinto zangaphakathi zepeyinti zidibana nesinyithi ukuze ziphumze umphezulu wesinyithi okanye zivelise izinto ezikhuselayo ukuphucula isiphumo sokukhusela sokwambathisa. Kwiivalvu ezineemfuno ezikhethekileyo, kufuneka unikele ingqalelo kulwakhiwo lwepeyinti ukuze uphephe iziphumo ezimbi kakhulu. Ukongeza, iivalvu zentsimbi ezisetyenzisiweyo kwimibhobho yeoyile zinokusebenza njengezithinteli zokubola kwezinto eziphilayo ngenxa yeemveliso zokubola eziveliswa phantsi kwesenzo seeoyile ezithile kunye nesenzo sokomisa sesepha zesinyithi.

04. Ukhuseleko lwe-electrochemical

Xa i-dielectric infiltrating coating idibana nomphezulu wesinyithi, i-electrochemical corrosion phantsi kwefilimu iya kwakheka. Iintsimbi ezinomsebenzi ophezulu kunentsimbi zisetyenziswa njengezizalisi kwiingubo, ezifana ne-zinc. Iya kudlala indima yokukhusela njenge-anode yokukhupha, kwaye iimveliso ze-corrosion ze-zinc yi-zinc chloride kunye ne-zinc carbonate esekwe kwityuwa, eziza kugcwalisa izikhewu kwifilimu kwaye zenze ifilimu iqine, zinciphise kakhulu ukugqwala kwaye zandise ubomi benkonzo yevalvu.

2. Iingubo ezisetyenziswa rhoqo kwiivalvu zesinyithi

Iindlela zokunyanga umphezulu weevalvu ziquka ikakhulu ukugqunywa kwepeyinti, ukugqunywa kwe-galvanizing kunye nokugqunywa kwe-powder. Ixesha lokukhusela lepeyinti lifutshane kwaye alinakusetyenziswa phantsi kweemeko zokusebenza ixesha elide. Inkqubo yokugqunywa kwe-galvanizing isetyenziswa kakhulu kwiipayipi. Zombini i-hot-dip galvanizing kunye ne-electro-galvanizing ziyasetyenziswa. Le nkqubo iyinkimbinkimbi. Unyango lwangaphambi konyango lusebenzisa iinkqubo zokuqhobosha kunye ne-phosphating. Kuya kubakho iintsalela ze-asidi kunye ne-alkali kumphezulu wesixhobo somsebenzi, okushiya ukugqunywa. Ingozi efihliweyo yenza umaleko we-galvaning ube lula ukuwa. Ukumelana nokugqunywa kwentsimbi ye-galvanizing yiminyaka emi-3 ukuya kwemi-5. Ugqunywa lwe-powder olusetyenziswa kwiivalvu zethu ze-Zhongfa luneempawu zokugqunywa okutyebileyo, ukumelana nokugqunywa, ukumelana nokukhukuliseka, njl.njl., ezinokuhlangabezana neemfuno zeevalvu phantsi kweemeko zokusetyenziswa kwenkqubo yamanzi.

01. Umzimba wevalvu we-epoxy resin coating

Ineempawu ezilandelayo:

·Ukumelana nokugqwala: Iibhari zentsimbi ezigqunywe yi-epoxy resin zinokumelana nokugqwala okuhle, kwaye amandla okubopha ngesamente ancitshiswa kakhulu. Zifanelekile kwiimeko zoshishino kwiindawo ezifumileyo okanye kwiindawo ezigqwalisayo.

·Ukunamathela okuqinileyo: Ubukho bamaqela e-polar hydroxyl kunye neebhondi ze-ether ezikwi-epoxy resin molecular chain kwenza ukuba inamathele kakhulu kwizinto ezahlukeneyo. Ukuncitshiswa kwe-epoxy resin xa inyangwa kuphantsi, uxinzelelo lwangaphakathi oluveliswayo luncinci, kwaye uphahla lomphezulu olukhuselayo alulula ukuwa nokusilela.

·Iimpawu zombane: Inkqubo ye-epoxy resin elungisiweyo yinto egqwesileyo yokukhusela ubushushu eneempawu eziphezulu ze-dielectric, ukumelana nokuvuza komphezulu, kunye nokumelana ne-arc.

·Imelana Nokubola: Inkqubo ye-epoxy resin evuselelweyo iyamelana nobuninzi bezinto ezibolayo kwaye ingasetyenziswa kwiimeko ezishushu zasetropiki.

02. Izinto zepleyiti yevalvu yenylon

Iishiti ze-nylon ziyakwazi ukumelana nokugqwala kakhulu kwaye zisetyenziswe ngempumelelo kwiindawo ezininzi ezifana namanzi, udaka, ukutya kunye nokukhupha ityuwa emanzini olwandle.

·Ukusebenza kwangaphandle: I-nylon plate coating ingaphumelela uvavanyo lokutshiza ngetyuwa. Ayizange ixobuke emva kokuntywiliselwa emanzini olwandle kangangeminyaka engaphezu kwama-25, ngoko ke akukho mhlwa kwiindawo zesinyithi.

·Ukumelana nokuguguleka: Ukumelana nokuguguleka okuhle kakhulu.

·Ukumelana nempembelelo: Akukho zimpawu zokuxobuka xa ibetha ngamandla.

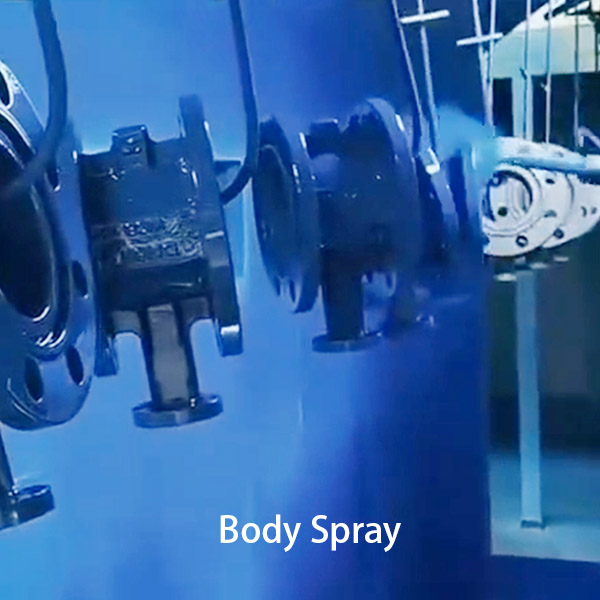

3. Inkqubo yokutshiza

Inkqubo yokutshiza yenziwa ngaphambi kokuba kusetyenziswe izinto ezisetyenzisiweyo → ukususa uthuli → ukufudumeza kwangaphambili → ukutshiza (iprimer - ukucheba - i-topcoat) → ukuqinisa → ukupholisa.

Ukutshiza Ukutshiza ikakhulu kusebenzisa ukutshiza nge-electrostatic. Ngokwesayizi yesixhobo sokusebenza, ukutshiza nge-electrostatic kunokwahlulwa kube ngumgca wokuvelisa ukutshiza nge-powder electrostatic kunye neyunithi yokutshiza nge-powder electrostatic. Ezi nkqubo zimbini ziyafana, kwaye umahluko ophambili yindlela yokutshintsha kwendlela yokusebenza. Umgca wokuvelisa ukutshiza usebenzisa ikhonkco lokudlulisela ukudlulisa ngokuzenzekelayo, ngelixa iyunithi yokutshiza iphakanyiswa ngesandla. Ubukhulu bengubo bulawulwa kwi-250-300. Ukuba ubukhulu bungaphantsi kwe-150 μm, ukusebenza kokukhusela kuya kuncipha. Ukuba ubukhulu bungaphezulu kwe-500 μm, ukunamathela kwengubo kuya kuncipha, ukumelana nempembelelo kuya kuncipha, kwaye ukusetyenziswa kwempuphu kuya kwanda.