A ivalve yebhabhathane enemigca epheleleyoibonisa isakhiwo esinemigca epheleleyo ngaphakathi komzimba wevalvu. Olu luyilo luyilelwe ngokukodwa usetyenziso olumelana nomhlwa.

"Umgca ngokupheleleyo" kuthetha ukuba kungekhona kuphela i-disc evalelwe ngokupheleleyo, kodwa kwakhona isihlalo sivalwe ngokupheleleyo, siqinisekisa ukuhlukaniswa okupheleleyo phakathi kweendaba kunye nesinyithi.

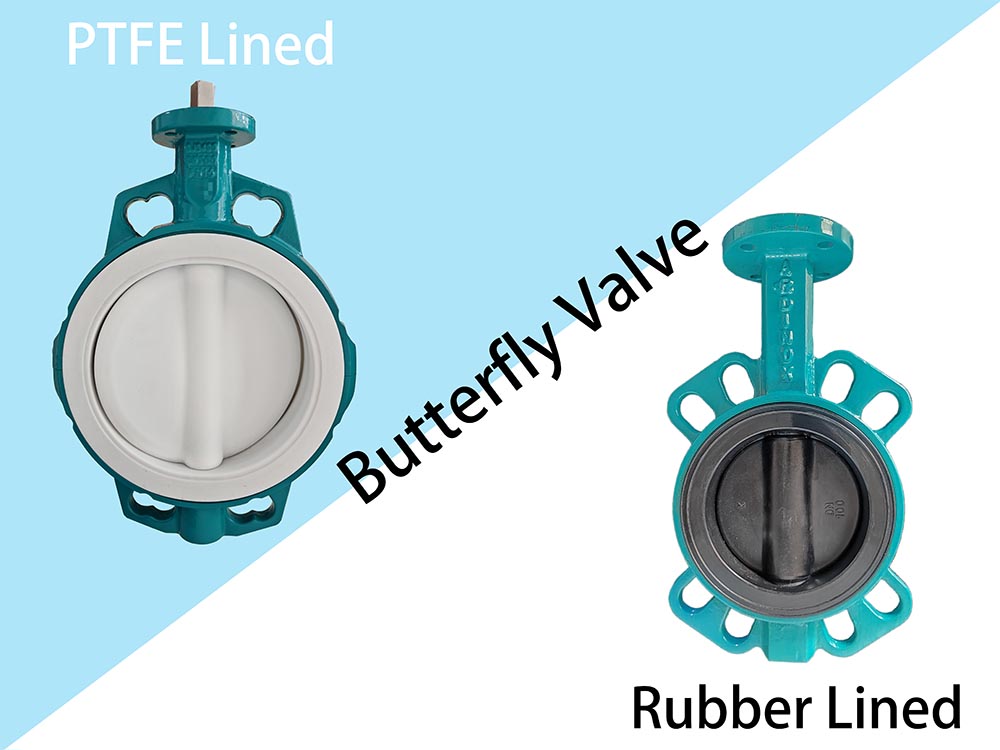

1. Izinto ezimbini eziqhelekileyo zombane

a. I-PTFE (i-polytetrafluoroethylene, i-perfluoroplastic) ivalve yebhabhathane elining

b. Ivalve yebhabhathane yerabha

| Uhlobo Lwezinto: | I-Polytetrafluoroethylene (PTFE) i-lining | Ilayini yerabha (umzekelo, EPDM, Viton, NBR) |

| Inkqubo yeLining | I-PTFE/PFA enyibilikileyo igalelwa kwi-dovetail groove emzimbeni/idiski, ukufikelela kwibhondi engenamthungo. | Emva koko ivulcanized (inyangelwe bubushushu) kwintsimbi, yenze itywina eliqinileyo. |

| Iimpawu eziphambili | -Ukumelana nokugqwesa kokugqwesa (ukuxhathisa phantse kuzo zonke iiasidi, iziseko, kunye nezinyibilikisi eziphilayo) - Ukumelana nobushushu obuphezulu (ubushushu bokusebenza obuqhubekayo ukuya kuthi ga kwi-180°C) - I-coefficient ephantsi ye-friction kunye ne-non-stick properties, ifanelekile kumajelo aphakamileyo acocekileyo

| -I-elasticity egqwesileyo kunye nokusebenza okugqwesileyo kokutywinwa (kulula ukufikelela kwi-zero ukuvuza) - Ixabiso eliphantsi kunye nokumelana nokunxiba kakuhle kwimidiya engagqwaliyo - Ukumelana nobushushu obuphantsi (ngokuqhelekileyo -20°C ukuya kwi-180°C, kuxhomekeke kuhlobo lwerabha)

|

| Imidiya Esebenzayo | Iiasidi ezinamandla (ezifana ne-sulfuric acid kunye ne-hydrochloric acid), iziseko ezomeleleyo, izinyibilikisi zezinto eziphilayo, ulwelo olucocekileyo oluphezulu. | amanzi, amanzi amdaka, iiasidi ezibuthathaka kunye neziseko, i-slurries, kunye nemidiya yebakala lokutya |

| Usetyenziso oluqhelekileyo | Ishishini leMichiza (ukudluliselwa kwe-asidi kunye ne-alkali), i-Pharmaceutical Industry (i-high-purity material transfer) | Ukucocwa kwamanzi (ukucocwa kwamanzi amdaka, amanzi ompompo), iiNkqubo zeHVAC, iShishini lokuTya kunye neSiselo, iMigodi (ukuhanjiswa kodaka) |

2. Amanyathelo eNkqubo eneenkcukacha ze-PTFE-lined Valve Discs

2.1 Ukulungiswa kweMetal Disc

a .. Yenza okanye umatshini we-disc yensimbi core, uqinisekise ukuba umphezulu ucocekile kwaye awunayo ioli kunye nokungcoliswa.

b.. Sika iigrooves (imilo ye-dovetail) kwindawo engundoqo ukubonelela ngamanqaku e-anchor ye-PTFE inaliti kwaye uyithintele ukuba ingawi.

2.2 Ukubunjwa komgubo we-PTFE kunye nokuBunjwa kwangaphambili

a. Beka inani elibalwe ngononophelo lwe-PTFE powder (okanye i-premix) kwi-mold, faka i-metal butterfly valve core, uze udibanise i-PTFE powder.

b. Kancinci faka i-vacuum (i-exhaust) kunye noxinzelelo (uxinzelelo okanye i-isostatic pressing) ukwenza i-embryo eluhlaza. Ukubunjwa kwe-Isostatic: Gxininisa isikhunta emanzini kwaye usebenzise uxinzelelo olufanayo kuwo onke macala (uxinzelelo lwamanzi oluqhubela phambili) ukuqinisekisa ukuba i-uniform kunye ne-dense structure (i-porosity ephantsi njenge-<1%).

2.3 Ukucula nokunyanga

a. Beka i-embryo eluhlaza kwi-oven kunye ne-sinter kwi-380 ° C kwiiyure ezingama-5-24 (kancinci ukwandisa izinga lokushisa ukuze ugweme ukuqhekeka).

b. Ukupholisa kancinane kwiqondo lobushushu begumbi ukuvumela i-PTFE ukuba ibe yikristale kwaye idibanise nentsimbi yentsimbi, iyenze i-coating engenamthungo (ubukhulu obulawulwayo bube yi-3-10mm, bulungelelaniswe ngokwemiqathango ye-vacuum).

2.4 Umatshini kunye nokuQeda:

Sebenzisa i-lathe okanye umatshini we-CNC ukwenza umatshini we-diameters yangaphakathi nangaphandle ukuqinisekisa ukuba i-disc kunye nesitulo silingana ngokugqibeleleyo (ukunyamezela kuqinile, umzekelo, ± 0.01mm).

2.5 Ukuhlolwa koMgangatho kunye noVavanyo:

a. Umlinganiselo wokutyeba: Qinisekisa ubuncinci belinen obuyi-3mm, okanye ngokwesiko.

b. Uvavanyo lwe-Spark: I-35,000 volts yokuvavanya ukuqina (akukho ukuphazamiseka kubonisa ukwamkelwa).

c. Uvavanyo lweVacuum / Amandla: Ukulinganisa iimeko zokusebenza ukujonga ukuvuza kunye nokungena (ngokuhambelana ne-EN 12266-1 okanye i-API 598).

d. Uvavanyo lokuqhuba (ukhetho): Ukumelana nomphezulu <10⁶Ω kwizicelo ezinobungqina bokudubula.

3. Amanyathelo eNkqubo eneenkcukacha kwii-EPDM-lined Discs

3.1 Ukulungiswa kweMetal Disc

a. Gcoba okanye umatshini undoqo wentsimbi ukuze uqinisekise indawo ecocekileyo, engenamhlwa.

b. Isanti okanye i-chemically etch surface (i-roughness Ra 3-6μm) ukukhuthaza ukunamathela kwe-EPDM.

3.2 EPDM Compound Application and Preforming

Ikhompawundi ye-EPDM enganyangekiyo (iphepha okanye ulwelo) ibekwe kwimold, ibhijele umbindi wentsimbi. Ukusebenzisa ukubunjwa koxinzelelo okanye ukugalela, ngokulinganayo usasaze i-compound phezu kwe-valve disc surface ukwenza umzimba oluhlaza. Gcina ubukhulu be-2-5 mm, uqinisekise ukugubungela imida yediski.

3.3 Ukunyanga

Umzimba oluhlaza ufakwe kwi-autoclave kwaye ushushu nge-steam okanye umoya oshushu (150-180 ° C, uxinzelelo> 700 psi, kwiiyure ze-1-4).

Inkqubo yokuphilisa idibanisa i-cross-link kunye nokunyanga i-EPDM, ikhemikhali kunye neyomatshini idibanisa kwi-core metal ukuze yenze i-seamless, i-line-piece lining. Yandisa ubushushu ngokucothayo ukunqanda amaqamza omoya okanye iintanda.

3.4 Ukugqitywa koMatshini

Emva kokupholisa, nciphisa imiphetho yangaphakathi nangaphandle usebenzisa i-CNC lathe ukuqinisekisa ukuba i-disc kunye nesihlalo silingana ngokugqibeleleyo (ukunyamezela ± 0.05 mm). Susa irabha engaphezulu kwaye ujonge iprofayili esemaphethelweni (i-Ni-Cu coating ikhethwa ngokuphuculwa kokumelana nokunxiba).

3.5 Ukuhlolwa koMgangatho noVavanyo

a. Ukutyeba kunye noVavanyo lwe-Adhesion: Ukulinganisa ubukhulu be-ultrasonic (ubuncinci be-2mm); Uvavanyo lwe-Tensile (amandla e-peel> 10 N / cm).

b. Ukuqinisekiswa kokuSebenza: Uvavanyo lwe-Bubble Tight Seal (i-API 598 eqhelekileyo); Uxinzelelo / uvavanyo lweVacuum (PN10-16, ukuchasana noxinzelelo olubi).

c. Uvavanyo lweMichiza / ukuguga: Ukucwiliswa kwi-asidi kunye ne-alkaline media, ukujonga ukwandiswa <5%; Ukuguga okuphezulu kobushushu (120 ° C, 72h).

4. Isikhokelo soKhetho

I-PTFE linings ifanelekile kwimidiya eyingozi kakhulu (efana ne-acids, alkalis, kunye ne-solvents), ngelixa ii-EPDM linings zifanelekile kumajelo asekelwe emanzini, aphakathi (njengamanzi kunye ne-acids dilute). Beka phambili ukuhambelana kweekhemikhali, ubushushu, uxinzelelo, kunye neendleko zokwandisa isicelo. IValve yaseZhongfa yenza iivalve zebhabhathane ezinemigca egcweleyo enewafer, iflange, kunye nelug ongakhetha kuzo. Nceda uqhagamshelane nathi ngayo nayiphi na imibuzo.

Ixesha lokuposa: Oct-28-2025