Iivalvu zebhabhathane ezixhathisayololona hlobo lusetyenziswa kakhulu lwevalvu yebhabhathane kwimibhobho yeshishini. Basebenzisa izixhobo ezinwebekayo ezinje ngerabha njengendawo yokutywina, baxhomekeke "kwizinto eziphathekayo" kunye "noxinzelelo lwesakhiwo" ukufezekisa ukusebenza kokutywinwa.

Eli nqaku alibonisi kuphela isakhiwo, ukusetyenziswa, kunye nezinto eziphathekayo, kodwa liphinda lihlalutye kulwazi oluqhelekileyo ukuya kwingqiqo enzulu.

1. Ukuqonda okuSisiseko kweeValuvu zebhabhathane eziZimeleyo (Ingcaciso emfutshane)

1.1 Ulwakhiwo olusisiseko

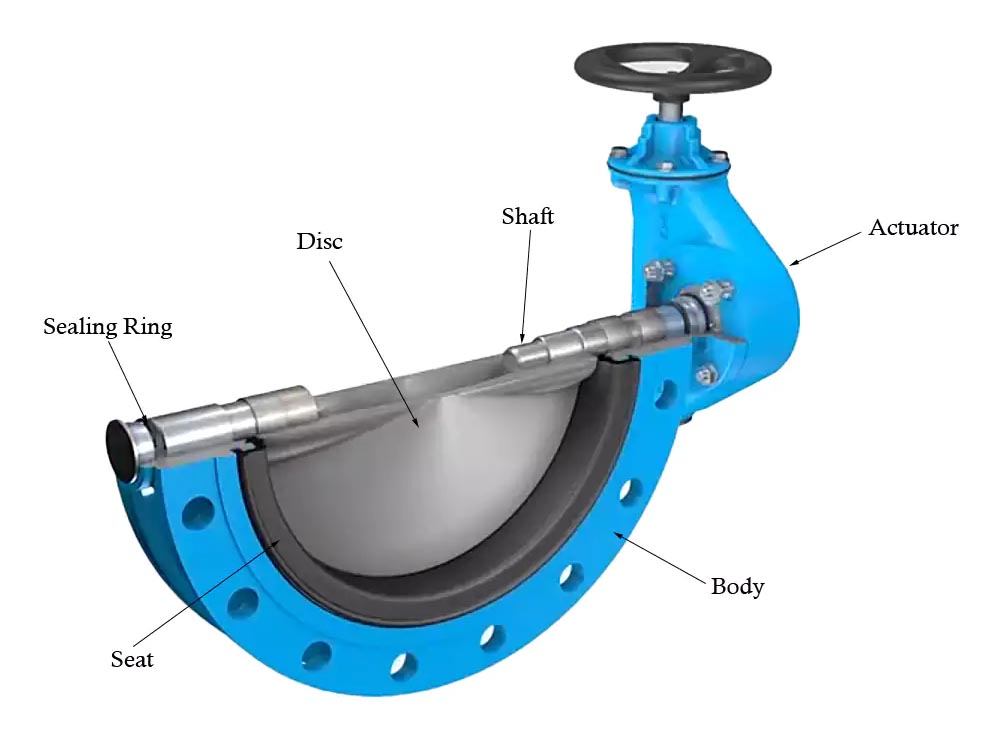

Umzimba weValve:Ngokuqhelekileyo uhlobo lwe-wafer, uhlobo lwe-lug, okanye uhlobo lwe-flanged.

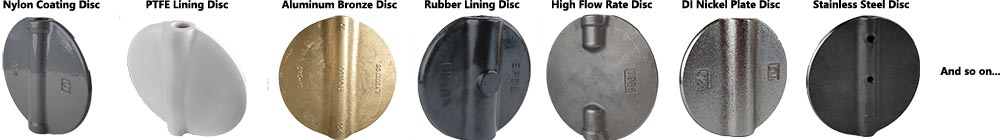

I-Valve Disc:Ipleyiti yentsimbi ejikelezayo ecinezela isihlalo serabha xa ivaliwe ukwenza itywina.

Isihlalo seValve:Yenziwe ngezinto ezi-elastic ezifana ne-NBR/EPDM/PTFE/Rubber Lined, esebenza ngokubambisana ne-valve disc.

Isiqu seValve:Ikakhulu isebenzisa ishafu-nye okanye uyilo oluphindwe kabini.

I-Actuator:Ukubamba, izixhobo zeentshulube, umbane, umoya, njl.

1.2 Iimpawu eziqhelekileyo

Inqanaba lokutywina lidla ngokufikelela kwiqanda lokuvuza.

Iindleko eziphantsi kunye noluhlu olubanzi lwezicelo.

Isetyenziswa kakhulu kwiinkqubo zoxinzelelo oluphantsi ukuya oluphakathi ezifana namanzi, umoya womoya, i-HVAC, kunye namashishini amachiza alula.

2. Iingcamango ezingezizo malunga neeValuvu zeBhavane eziZimeleyo

2.1 Undoqo wokutywinwa kukomelela kwerabha

Abantu abaninzi bakholelwa ukuba: "Izihlalo ezizinzileyo zithembele ekuqiniseni irabha yokutywinwa."

Undoqo wokwenyani wokutywinwa ngulo:

Umzimba wevalvu + umgama osembindini wevalve + ubukhulu bediskhi yevalve + indlela yokufakela isihlalo sevalve

Ngokudibeneyo yenza "indawo yoxinzelelo elawulwayo".

Ngokulula:

Irabha ayinakukhululeka kakhulu okanye iqine kakhulu; ixhomekeke "kwindawo yokutywina yokutywina" elawulwa ngokuchaneka komatshini.

Kutheni le nto ibalulekile?

Uxinzelelo olungonelanga: Ukuvuza kweValve xa ivaliwe.

Uxinzelelo olugqithisileyo: I-torque ephezulu kakhulu, ukuguga kwangaphambili kwerabha.

2.2 Ngaba imilo yediskhi ephuculwe ngakumbi iwonga amandla?

Umbono oqhelekileyo: Iidiski ze-valve ezilungelelanisiweyo zinokunciphisa ukulahleka koxinzelelo.

Oku kuyinyani ngokwethiyori ye "fluid mechanics", kodwa ayisebenzi ngokupheleleyo kusetyenziso lwenyani lweeValve zeBhavane eziQinisayo.

Isizathu:

Owona mthombo uphambili wokulahleka koxinzelelo kwiivalvu zebhabhathane ayiyomilo yediski yevalve, kodwa "isiphumo setonela encinci" esibangelwa kukucutheka kwerubha yesitulo sevalve. I-disc ye-valve ibe yincinci kakhulu inokungaphumeleli ukubonelela ngoxinzelelo olwaneleyo loqhagamshelwano, okunokuthi kuholele kwimigca yokutywinwa engapheliyo kunye nokuvuza.

I-disc ye-valve ehlanjululwayo ingabangela amanqaku abukhali oxinzelelo kwi-rubber, ukunciphisa ixesha lokuphila kwayo.

Ke ngoko, uyilo lweevalvu zebhabhathane ezihleli ngokuthambileyo lubeka phambili "ukuzinza komgca wokutywina" ngaphezulu kokulungelelanisa.

2.3 Iivalve zebhabhathane ezihleli ngokuthambileyo zinesakhiwo esisembindini kuphela

Kuhlala kuthiwa kwi-intanethi ukuba iivalve zebhabhathane eccentric kufuneka zisebenzise izitywina eziqinileyo zentsimbi.

Nangona kunjalo, amava obunjineli bokwenyani abonisa ukuba:

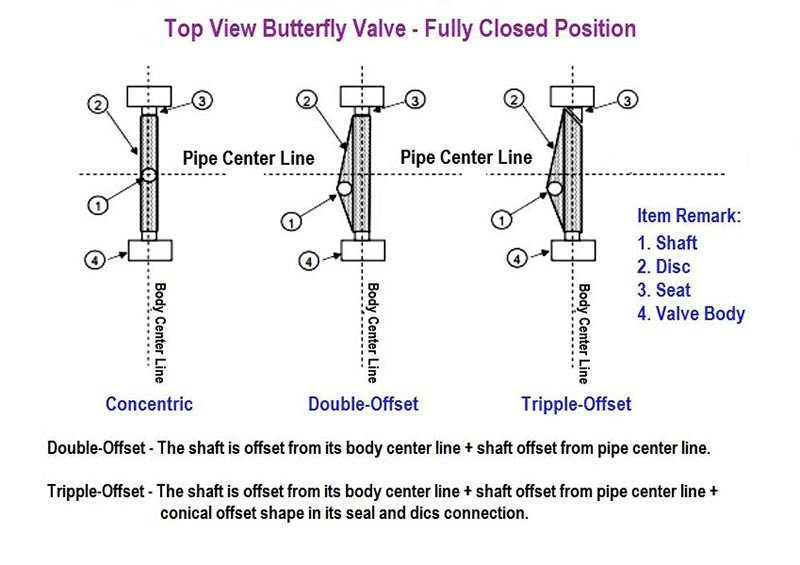

I-eccentricity ephindwe kabini iphucula ngokubonakalayo ubomi beeValve zeButterfly Resilient.

Isizathu:

I-double eccentricity: I-disc ye-valve idibanisa kuphela i-rubber ngexesha lokugqibela kwe-2-3 ° yokuvala, ukunciphisa kakhulu ukungqubuzana.

Itorque esezantsi, ekhokelela kukhetho oluthe kratya lwe-actuator.

2.4 Eyona nto ithathelwa ingqalelo kwisitulo serabha ligama elithi "material name"*

Uninzi lwabasebenzisi lugxile kuphela kwi:

EPDM

NBR

Viton (FKM)

Kodwa eyona nto ichaphazela ubomi bobomi yile:

2.4.1 Ukuqina konxweme:

Ngokomzekelo, i-Shore A hardness ye-EPDM ayikho imeko "yokuthambileyo kungcono." Ngokuqhelekileyo, i-65-75 yindawo efanelekileyo yokulinganisa, ukufezekisa ukuvuza kwe-zero kuxinzelelo oluphantsi (PN10-16).

Ithambile kakhulu: Itorque ephantsi kodwa ikrazuka lula. Kwiincopho zoxinzelelo oluphezulu (> 2 MPa) okanye iimeko ezinobunzima, irabha ethambileyo ixinzelelwe ngokugqithisileyo, ibangela i-extrusion deformation. Ngaphezu koko, amaqondo obushushu aphezulu (>80°C) ayenze ithambe ngakumbi irabha.

Kunzima kakhulu: Kunzima ukutywina, ngakumbi kwiinkqubo zoxinzelelo oluphantsi (<1 MPa), apho irabha ayinakunyanzeliswa ngokwaneleyo ukuze yenze i-interface engangeni moya, ekhokelela kwi-micro-leakage.

2.4.2 Ubushushu beVulcanization kunye nexesha lokunyanga

Ukushisa kwe-Vulcanization kunye nexesha lokunyanga ukuxhamla kwe-rubber ye-molecular chain chain, echaphazela ngokuthe ngqo ukuzinza kwesakhiwo senethiwekhi kunye nokusebenza kwexesha elide. Uluhlu oluqhelekileyo luyi-140-160 ° C, imizuzu engama-30-60. Amaqondo obushushu aphezulu kakhulu okanye asezantsi kakhulu akhokelela ekunyangeni okungalinganiyo kunye nokuguga okukhawulezileyo. Inkampani yethu ngokubanzi isebenzisa i-vulcanization yamanqanaba amaninzi (ukunyanga kwangaphambili kwi-140 ° C, ilandelwa yi-post-curing kwi-150 ° C). 2.4.3 Iseti yoxinzelelo

Iseti yokunyanzeliswa ibhekisela kumlinganiselo wokuguqulwa okusisigxina ukuba i-rubber iphantsi koxinzelelo oluqhubekayo (ngokuqhelekileyo i-25% -50% yoxinzelelo, ihlolwe kwi-70 ° C / 22h, i-ASTM D395) kwaye ayikwazi ukubuyisela ngokupheleleyo. Ixabiso elifanelekileyo leseti yoxinzelelo ngu <20%. Eli xabiso "yi-bottleneck" yokutywinwa kwexesha elide levalve; ixesha elide uxinzelelo oluphezulu lukhokelela kwizikhewu ezisisigxina, zenze iindawo zokuvuza.

2.4.4 Amandla Okuqina

A. Amandla Okuqina (ngokuqhelekileyo> 10 MPa, ASTM D412) lolona xinzelelo luphezulu irabha inokumelana nayo ngaphambi kokuphuka kwe-tensile, kwaye ibalulekile ekuxhathiseni ukunxiba kunye nokukrazula kwesihlalo sevalve. Isiqulatho serabha kunye ne-carbon black ratio imisela amandla okuqina kwesitulo sevalve.

Kwiivalvu zebhabhathane, liyaxhathisa ukucheba ngomphetho wediski yevalve kunye nefuthe lolwelo.

2.4.5 Eyona ngozi inkulu efihlakeleyo yeevalvu zebhabhathane kukuvuza.

Kwiingozi zobunjineli, ukuvuza akusoloko kuyingxaki enkulu, kodwa kunoko ukwanda kwetorque.

Eyona nto ikhokelela kukusilela kwenkqubo yile:

Ukunyuka ngequbuliso kwitorque → umonakalo wegiya yeentshulube → ukukhubeka kwe actuator → ivalve jamming

Kutheni i-torque inyuka ngokukhawuleza?

- Ukwandiswa kobushushu obuphezulu kwesitulo sevalvu

- Ukufunxwa kwamanzi kunye nokwandiswa kwerabha (ingakumbi i-EPDM ekumgangatho ophantsi)

- Ukuguqulwa okusisigxina kwerabha ngenxa yokunyanzeliswa kwexesha elide

- Uyilo olungafanelekanga lomsantsa phakathi kwesikhondo sevalve kunye nediski yevalvu

-Isitulo sevalve asiqhekezwanga kakuhle emva kokutshintshwa

Ngoko ke, "i-torque curve" luphawu olubaluleke kakhulu.

2.4.6 Ukuchaneka komatshini wokuchaneka kwevalvu ayibalulekanga kangako.

Abantu abaninzi bakholelwa ngempazamo ukuba ukutywinwa kweevalvu zebhabhathane ezihleli ngokuthambileyo kuxhomekeke kakhulu kwirabha, ngoko ke iimfuno zokuchaneka komatshini womzimba wevalvu azikho phezulu.

Oku kuphosakele ngokupheleleyo.

Ukuchaneka komzimba wevalvu kuchaphazela:

Ubunzulu begroove yesitulo sevalvu → ukutenxa koxinzelelo lokutywina, kubanga lula ulungelelwaniso olungalunganga ngexesha lokuvula nokuvala.

Ukunganelanga komphetho wegroove → ukukrwela ngexesha lofakelo lwesitulo sesivalo

Imposiso embindini womgama wediskhi yevalvu → uqhagamshelwano olugqithisileyo lwasekuhlaleni

2.4.7 Undoqo "werabha/iivalvu zebhabhathane ezinomgca we-PTFE" yidiski yevalve.

Undoqo werabha ngokupheleleyo okanye ulwakhiwo olunemigca ye-PTFE ayikuko ukuba "unendawo enkulu ebonakala i-resistant-resistant," kodwa ukuthintela i-medium ekungeneni kwi-micro-channels ngaphakathi kwi-valve body. Iingxaki ezininzi ezineevalve zebhabhathane ezingabizi azikho ngenxa yomgangatho ophantsi werabha, kodwa kunoko:

"Isithuba esimile okwe wedge" ekudibaneni kwesitulo sevalvu kunye nomzimba awulungiswanga kakuhle.

Ukhukuliseko lolwelo oluhlala ixesha elide → imikrozo emincinci → ukugqabhuka kwerabha kunye nokugqabhuka

Inyathelo lokugqibela kukungaphumeleli kwendawo yesitulo sevalvu.

3. Kutheni iResilient Butterfly Valves isetyenziswa kwihlabathi jikelele?

Ngaphandle kweendleko eziphantsi, izizathu ezithathu ezinzulu zezi:

3.1. Ukunyamezela impazamo kakhulu

Xa kuthelekiswa nezitywina zetsimbi, izitywina zerabha, ngenxa yokuqina kwazo okugqwesileyo, zinonyamezelo oluluqilima lokuphambuka kofakelo kunye nokukhubazeka okuncinci.

Nkqu neempazamo zokwenziwa kombhobho kwangaphambili, ukunxaxha kweflange, kunye noxinzelelo lwebholiti olungalinganiyo lufunxwa kukunwebeka kwerabha (ewe, oku kulinganiselwe kwaye akufuneki, kwaye kuya kubangela umonakalo othile kumbhobho kunye nevalve ekuhambeni kwexesha).

3.2. Eyona nto ilungele ukuguquguquka koxinzelelo lwenkqubo

Iimpawu zerabha azikho "njenge-brittle" njengezitywina zetsimbi; bahlawula ngokuzenzekelayo umgca wokutywina ngexesha lokutshintsha koxinzelelo.

3.3. Elona xabiso liphantsi lilonke lomjikelo wobomi

Iivalvu zebhabhathane ezitywiniweyo zomelele ngakumbi, kodwa iindleko kunye neendleko ze-actuator ziphezulu.

Xa kuthelekiswa, iindleko zotyalo-mali zizonke kunye nokugcinwa kweeValve zeButterfly eziQinisayo zinoqoqosho ngakumbi.

4. Isiphelo

Ixabiso leIivalvu zebhabhathane ezikwaziyo ukunyamezelaAyisiko "utywino oluthambileyo"

Iivalvu zebhabhathane ezitywiniweyo zinokubonakala zilula, kodwa iimveliso ezigqwesileyo zixhaswa bubunjineli bebakala elibukhali, kubandakanya:

Uyilo lwezowuni yoxinzelelo oluchanekileyo

Ukusebenza kwerabha elawulwayo

Ukuhambelana kwejiyometri yomzimba wevalvu kunye nesiqu

Inkqubo yokuhlanganisa isihlalo sevalve

Ulawulo lweTorque

Uvavanyo lomjikelo wobomi

Le yimiba ephambili emisela umgangatho, hayi "igama lezinto eziphathekayo" kunye "nesakhiwo sembonakalo".

QAPHELA:* IDATHA ibhekisa kule webhusayithi:https://zfavalves.com/blog/key-factors-that-determine-the-quality-of-soft-seal-butterfly-valves/

Ixesha lokuposa: Dec-09-2025