Ivalvu yebhabhathane ivavanywa ngeendlela ezininzi ukusuka ekuvelisweni ukuya ekuthunyelweni ukuqinisekisa umgangatho wayo kunye nokuthembeka kwayo. Uhlolo olupheleleyo lugubungela izinto ezisemgangathweni ezifana nezinto, ukugquma, inkangeleko, irabha, uxinzelelo, kunye nobukhulu, kunye nokusebenza kokuvala, inkangeleko, i-torque, ubulukhuni, ubukhulu, ukuhlanganiswa, ukuchaneka kwentambo kunye neflange, kunye neempawu zokulandelela.

Inkqubo yokuhlola ingenziwa ngolu hlobo lulandelayo: Ukuhlolwa kwezinto eziluhlaza → Ukuhlolwa kokucubungula → Uvavanyo lokusebenza kwemveliso olugqityiweyo → Ukwamkelwa kokugqibela. Inkalo nganye ichazwa kunye neendlela ezithile kunye nemigangatho.

Inkqubo yoHlolo lweValve yeButterfly

1. Ukuhlolwa kwezinto eziluhlaza

1.1 Injongo

Ukuqinisekisa ukuba izinto ezisetyenziswa kudala ezifana nomzimba wevalvu, ipleyiti yevalvu, isiqu sevalvu, kunye neringi yokutywina ziyahlangabezana neemfuno ezisemgangathweni.

1.2 Izinto zokuhlola:

-Uhlalutyo loBume beKhemikhali: Usebenzisa i-spectrometer okanye indlela yohlalutyo lwekhemikhali, qinisekisa isatifikethi sezinto ukuqinisekisa ukuthotyelwa kwemigangatho yezinto ze-ASTM/GB/EN.

-Uvavanyo Lokusebenza Koomatshini: Uvavanyo lwesampuli lwenziwa kwiimvavanyo zokuxinana, ukujiya, ukunwebeka, kunye neziphumo.

-Ukuchongwa kwezinto kunye nokulandelelwa kwazo: Ibhetshi nganye yezinto ezikrwada kufuneka ichongwe ngenombolo yesithando sayo ukuqinisekisa ukulandelelwa kwazo.

-Uhlolo lweMetallographic (Onganyanzelekanga): Hlola izinto ezifakelweyo ukuze ubone iziphene ezifana nokuqukwa kwe-slag kunye ne-porosity.

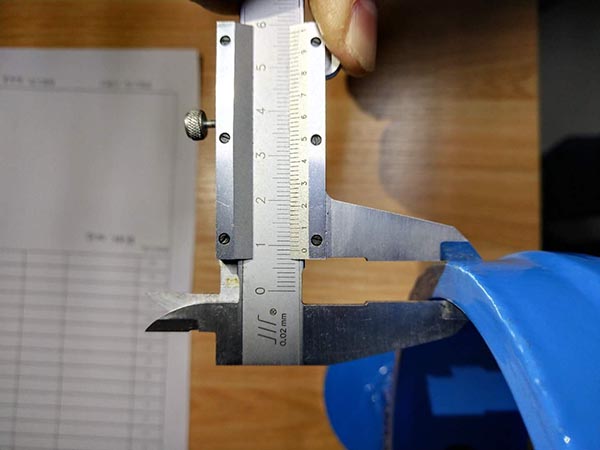

2. Uvavanyo lweMilinganiselo

Izixhobo: Ii-calipers zeVernier, i-inside diameter gauge, i-depth gauge.

2.1 Injongo

Ukuqinisekisa ukuba ubungakanani bemveliso buhambelana nemizobo eqhelekileyo ukuze kube lula ukuyifaka nokutshintshiselana.

2.2 Izinto zokuhlola

Ubude bomzimba wevalvu (ubukhulu bobuso ngobuso)

Isithuba somngxuma woqhagamshelo lweFlange, ububanzi bomngxuma, iinkcukacha zomsonto

Ubukhulu bepleyiti yevalvu kunye nokususwa komphetho

Ubunzulu bomsonto kunye nokunyamezelana kwawo

3. Ukuhlolwa kweRabha kunye neSitulo

Izinto eziqhelekileyo: EPDM, NBR, VITON, PTFE.

3.1 Injongo

Ukuqinisekisa ukumelana noxinzelelo, ukumelana nobushushu, kunye nokumelana nokugqwala kwezinto zokuvala.

3.2 Izinto zokuhlola

Uqinisekiso lwezinto

Jonga ukuba umphezulu uthambile, ukungabikho kwamaqhuqhuva, amaqamza, kunye nokungcola.

Hlola ubukhulu obuphambili beringi yokutywina, njengobubanzi obunqamlezileyo kunye nobubanzi obungaphakathi nobungaphandle.

Ubunzima berabha (umvavanyi wobunzima baseShore), iseti yoxinzelelo, amandla okutsalwa, njl.njl.

Uvavanyo lokumelana nokukrala

Ukulingana kunye nokuthembeka kweplate yevalvu

4. Ukuhlolwa kokwaleka

4.1 Injongo

Ukuqinisekisa ukuba i-corrosion iyamelana nokugqwala, ukunamathela, kunye nobukhulu be-coating kuhambelana nemigangatho.

4.2 Izinto zokuhlola

Unyango lwangaphambi kokucocwa komphezulu (ukususwa komhlwa) umgangatho ngaphambi kokutshiza (i-Sa2.5 okanye ngaphezulu, akukho bukhulu okanye umhlwa obonakalayo)

Ubukhulu bokugquma emva kokutshiza (kusetyenziswa igeyiji yobukhulu bokugquma)

Ukuncamathela kwengubo (uvavanyo olunqamlezileyo, isithuba se-1mm, indawo yokuxobula ingubo ≤5% emva kokususwa kwetheyiphu)

Ukuhlolwa kwenkangeleko (ukuwa, imingxunya yepin, amaqamza, ixolo leorenji, umahluko wombala)

Uvavanyo lokuqina kwengubo kunye nokuchasana nokugqwala kwetyuwa

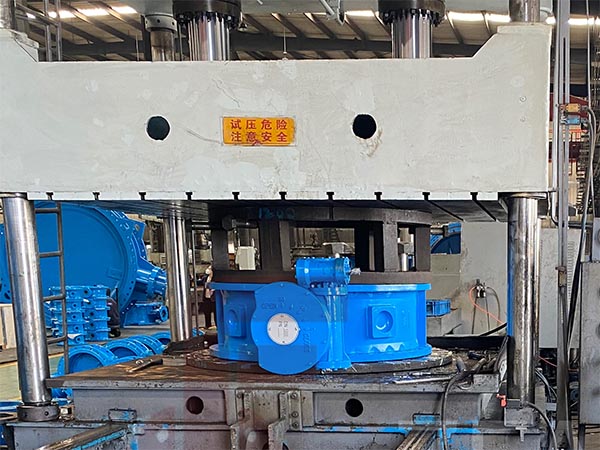

5. Uvavanyo loxinzelelo kunye nokuvuza

5.1 Injongo

Ukuqinisekisa ukuba ivalvu ayivuzi phantsi koxinzelelo olulinganisiweyo.

5.2 Iikhrayitheriya zoKwamkelwa

Umzimba wevalvu kunye nazo zonke izinto ezithwala uxinzelelo akufuneki zibe nomonakalo kwisakhiwo, ukuguquka okungapheliyo, okanye ukuvuza.

5.3 Izinto zovavanyo

Uvavanyo lwaMandla eShell: Uvavanyo lwe-hydrostatic oluphindwe ka-1.5 kuxinzelelo olulinganisiweyo, ixesha lokubamba liyi-≥ imizuzu emi-2.

Uvavanyo lokutywina: Uvavanyo lokutywina phambili nangasemva ngoxinzelelo oluphindwe ka-1.1.

Uvavanyo lokuQina koMoya: Fumana ukuvuza okuncinci usebenzisa umoya okanye i-nitrogen kwi-0.6 MPa.

Umgangatho wokuVuthela okungekho Mgangatho: Iyahambelana neemfuno ze-API 598 / ISO 5208.

6. Uvavanyo lweTorque oluSebenzayo

6.1 Injongo

Ukuqinisekisa ukuba i-torque yokuvula neyokuvala iyahlangabezana nomgangatho kwaye ihambelana neemfuno zoyilo, ukuqinisekisa ukuba iyunithi yokuqhuba iyahambelana.

Indlela yoVavanyo

Kulinganiswa kusetyenziswa ii-torque wrenches kunye nee-torque meter ezifana nee-electric actuators; thelekisa i-torque yoyilo kunye ne-torque elinganisiweyo.

7. Ukujonga okubonakalayo nokumakishwayo

7.1 Injongo

Ukuqinisekisa umgangatho wenkangeleko kunye neenkcukacha zokumakisha.

7.2 Izinto zovavanyo

Akukho zingcoliso zentsimbi, i-welding slag, amabala eoyile, okanye ezinye izinto ezingcolileyo ngaphakathi.

Akukho mifantu, ii-burrs, okanye umhlwa. Ubuthambile bomphezulu kunye nokungaguquguquki kombala. Ulwazi lwepleyiti yegama (imodeli, umlinganiselo woxinzelelo, izinto, utolo lwendlela yokuhamba) lucacile, luphelele, kwaye lukhuselekile.

8. Uvavanyo Lokusebenza

8.1 Injongo

Ukuqinisekisa ukuthembeka nokusebenza kokuhamba kwevalvu.

8.2 Izinto zovavanyo

Ukuvulwa nokuvalwa kwepleyiti yevalvu

Ukuchaneka kokubekwa kwesithuba seValve

Umlinganiselo wokumelana nokuhamba kwamanzi (ixabiso le-Cv)

Ukungaguquguquki kwesikhokelo sokuhamba kolwelo

9. Uhlolo lokugqibela kunye novavanyo lwefektri

9.1 Injongo

Ukumisela ngokupheleleyo ukuba imveliso ifanelekile na kwaye ikulungele ukuthunyelwa.

9.2 Ibandakanya

Uhlolo lweerekhodi zovavanyo

Ukuncamathisela isatifikethi sokuvumelana kunye neelebhile zovavanyo

Ingaba ukupakisha kuyakhusela ngokufanelekileyo ekonakalisweni ngexesha lokuthuthwa, kwaye ingaba kukho izigqubuthelo zokukhusela ebusweni beflange kunye neziphelo ezinemisonto.

Ixesha leposi: Okthobha-28-2025