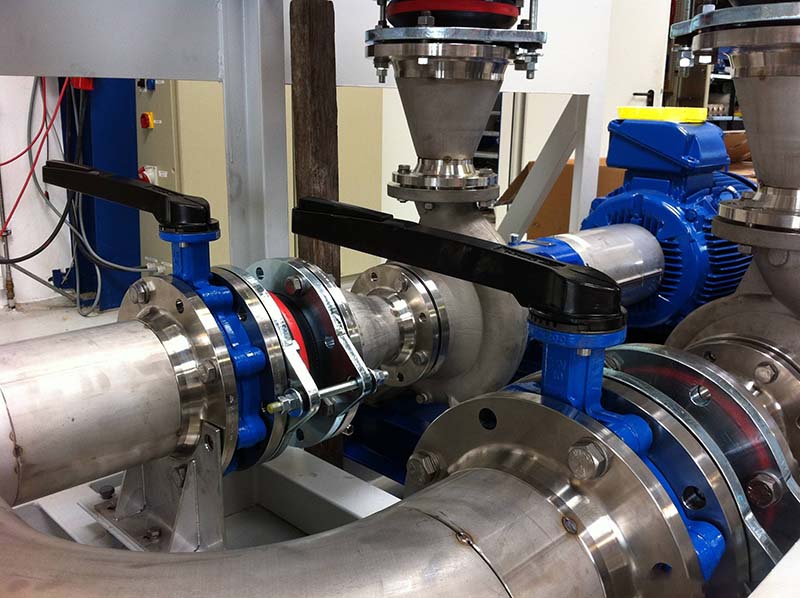

Iivalvu zebhabhathane zisetyenziswa kakhulu kumashishini afana nokucoca amanzi, ioyile negesi, i-HVAC, kunye nokucubungula iikhemikhali ngenxa yoyilo lwazo oluncinci kunye nokuhamba kakuhle kombane kunye nolawulo olungabizi kakhulu.

Nangona kunjalo, enye yezona ngxaki zixhaphakileyoiivalvu zebhabhathaneukuvuza. Ukuvuza kungenzeki ngaphakathi (ngesihlalo sevalvu) okanye ngaphandle (kujikeleze isiqu sevalvu okanye umzimba wevalvu). Ukuvuza kungaba kuncinci okanye kube kukhulu, okubangela ukungasebenzi kakuhle kwenkqubo, okanye iingozi ezinkulu zokhuseleko, imiba yokusingqongileyo, okanye ixesha lokungasebenzi elibizayo.

Ke ngoko, ukuqonda izizathu eziphambili zokuvuza kunye nokusebenzisa izisombululo ezisebenzayo kubalulekile ukuqinisekisa ukusebenza okuthembekileyo kwevalvu.

---

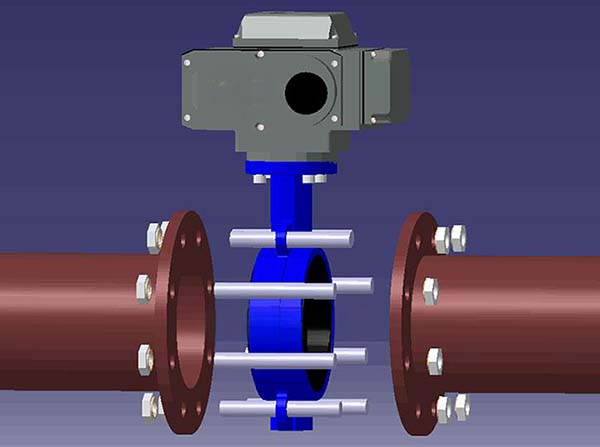

Iintlobo zokuvuza kwevalvu yebhabhathane

Ngaphambi kokuba singene kwiimbangela kunye nezisombululo, masiqale sihlele ukuvuza okuqhelekileyo kwiivalvu zeebhabhathane:

a. Ukuvuza Kwangaphakathi: Ulwelo ludlula kwivalvu xa lukwindawo evaliweyo, nto leyo ebonisa ukuba isihlalo sevalvu okanye idiski ayinakwenza uphawu oluqinileyo.

b. Ukuvuza Kwangaphandle: Ulwelo luphuma emzimbeni wevalvu, ludla ngokujikeleza isiqu sevalvu, ukupakisha, okanye uqhagamshelo lweflange, nto leyo ebeka emngciphekweni isitywini.

Zombini ezi ntlobo zokuvuza zinokuvela kuyilo, ukufakelwa, ukusebenza, okanye izinto ezinxulumene nokugcinwa.

Ngezantsi, siza kuphonononga izizathu eziphambili kunye nezisombululo ezifanelekileyo kuhlobo ngalunye lokuvuza.

---

1. Izitywini ezigugileyo okanye ezonakeleyo

Isizathu esiqhelekileyo sokuvuza kwangaphakathi kukuwohloka kwezinto zokutywina iivalvu (ezifana nee-elastic liners okanye izihlalo zesinyithi).

1.1 Izizathu

- Ukonakala kwezinto: Ukuvezwa ixesha elide kulwelo olunobuthi, amaqondo obushushu aphezulu okanye imitha ye-ultraviolet kunokubangela ukuba izitywini ziqine, ziqhekeke okanye zilahlekelwe bubuthambile.

- Izinto ezirhabaxa: Izinto eziqulethe isanti, igrabile okanye ezinye izinto ziya kutshabalalisa izitywini ngokuhamba kwexesha.

- Ukwaluphala: Nokuba phantsi kweemeko ezingenzima kangako, izitywini ziya kuwohloka ngokwendalo ngokuhamba kwexesha, nto leyo enciphisa amandla azo okulingana nediski yevalvu. Oku kukwaluphala kwendalo okungenakuphepheka.

- I-torque egqithisileyo: I-torque ye-actuators yombane, ye-pneumatic kunye nezinye izixhobo ezikhethiweyo inkulu kakhulu, kwaye idiski yevalvu ifaka uxinzelelo olukhulu kwisihlalo sevalvu xa ivala, nto leyo ebangela ukuba isihlalo sevalvu sijike okanye sikrazuke. Nokuba sisetyenziswa ngesandla, ukusebenzisa i-torque egqithisileyo kwiivalvu zebhabhathane ezinkulu kunokubangela ukuguquka okanye umonakalo kwisihlalo sevalvu.

1.2 Izisombululo

- Ukukhetha izinto: Khetha izinto zokuvala ezihambelana nolwelo kunye neemeko zokusebenza. Umzekelo, sebenzisa i-PTFE yokumelana neekhemikhali, i-EPDM yokusetyenziswa kwamanzi, kunye ne-Viton yolwelo olusekelwe kwioyile.

- Ulondolozo oluqhelekileyo: Sebenzisa inkqubo yolondolozo lokuthintela ukuhlola nokutshintsha izitywini ngaphambi kokuba zingasebenzi. Oku kubaluleke kakhulu kwiindawo ezinzima.

- Ukwaleka okukhuselekileyo: Kwizicelo ezirhabaxa, cinga ngokusebenzisa iivalvu ezinezihlalo ezigqunyiweyo okanye eziqinileyo ukuze wandise ubomi bezitywini.

- Lungiselela i-actuator: Ngokwedatha ye-torque ye-butterfly valve enikwe ngumvelisi, khetha i-actuator ene-torque efanelekileyo, okanye ukhethe i-actuator enokhuseleko lwe-torque. Ukongeza, xa usebenza ngesandla, kufuneka kuphetshwe amandla agqithisileyo. I-Zfa icebisa ukuba ukuba awuqinisekanga, ungasebenzisa i-actuator ye-handle okanye ye-worm gear enomlinganiselo we-torque.

----

2. Ufakelo olungafanelekanga

Ukuvuza kudla ngokubangelwa ziimpazamo ngexesha lokufakwa kweevalvu, ezichaphazela izitywino zangaphakathi nezangaphandle.

2.1 Izizathu

- Ukungalingani: Ukuba ivalvu ayihambelananga kakuhle nombhobho, idiski isenokungahlali kakuhle, nto leyo ebangela ukuvuza kwangaphakathi.

- I-torque enganelanga: Ukuqiniswa okungonelanga kwee-bolts ze-flange kunokubangela ukuvuza kwangaphandle kwindawo yokujonga umbhobho wevalvu.

- Ukuqina kakhulu: I-torque egqithisileyo inokubangela ukuguquka komzimba wevalvu okanye isihlalo, nto leyo enokuthintela idiski ukuba ivaleke ngokupheleleyo kwaye ibangele ukuvuza kwangaphakathi.

2.2 Isisombululo

- Ukujonga ulungelelwaniso: Ngexesha lokufakela, sebenzisa isixhobo sokulungelelanisa ukuqinisekisa ukuba ivalvu iphakathi kumbhobho. Kwakhona kuyimfuneko ukuqinisekisa ukuba idiski ihamba ngokukhululekileyo ngaphandle kokuqhagamshelana nodonga lombhobho.

- Iinkcukacha zeTorque: Landela ixabiso leTorque elicetyiswayo ngumvelisi kwiibholithi zeflange kwaye usebenzise isikrufu seTorque esilinganisiweyo ukuze ufezekise ukucinezelwa okufanayo kwegasket.

- Ukukhetha iiGasket: Sebenzisa iiGasket ezikumgangatho ophezulu, ezine-elastic ephezulu ezihambelana nezixhobo zevalvu kunye nepayipi. Kwakhona qiniseka ukuba ubungakanani begasket bufanelekile ukuze uphephe ukucinezelwa okanye ukuvuleka okukhulu.

----

3. Ukuphazamiseka kweDiski

Ukuvuza kwangaphakathi kungenzeka xa idiski ingakwazi ukuvala ngokupheleleyo ngenxa yokuphazamiseka okubonakalayo kumbhobho okanye iflange ejikelezileyo.

3.1 Isizathu

- Ukungalingani kobubanzi bombhobho: Ukuba i-ID yombhobho incinci kakhulu, idiski ingabetha eludongeni lombhobho xa ivala.

- Uyilo lweFlange: Iiflanges ezinobuso obuphakanyisiweyo okanye iindawo zokutshatisa ezingalinganiyo zinokubangela ukuba idiski ingashukumi.

- Ukuqokelelana kwenkunkuma: Izinto eziqinileyo okanye izikali eziqokelelana ngaphakathi kwivalvu zinokuthintela idiski ukuba ihlale kakuhle.

3.2 Isisombululo

- Ukuqinisekiswa kokuhambelana: Ngaphambi kokufakela, qinisekisa ukuba ububanzi bediski yevalvu buyahambelana ne-ID yombhobho.

- Ukulungiswa kweFlange: Landela imigangatho efana ne-ANSI okanye i-DIN ukuze usebenzise iiflange ezisicaba okanye iigasket ukuqinisekisa ukuba idiski icacile.

- Umsebenzi wokucoca: Hlamba inkqubo ngaphambi kokuba kusetyenziswe ivalvu ukuze kususwe ubumdaka, kwaye ufake izihluzi ezisezantsi ukuba iimeko ziyavuma ukuthintela ukuqokelelana kwixesha elizayo.

4. Ukupakisha isiqu okungaphumeleli

Ukuvuza kwangaphandle kudla ngokuvela ngeenxa zonke zesiqu sevalvu, okubangelwa ziingxaki zokupakishwa okanye izitywino ezithintela ulwelo ukuba lungaphumi ecaleni kwe-axis.

4.1 Isizathu

- Ukuguguleka: Ekuhambeni kwexesha, izinto zokupakisha ezifana ne-PTFE okanye i-graphite ziyaguguleka ngenxa yokunyakaza kwesiqu okanye uxinzelelo.

- Ukuguquguquka kobushushu: Ngokusekelwe kumgaqo wokwandiswa nokuncipha kobushushu, ukuguquguquka kobushushu okuphindaphindiweyo kunokubangela ukuba ukupakisha kunciphe, kukhululeke, kwaye kuqhekeke.

- Ukulungiswa okungafanelekanga: Ukuba i-packing gland ikhululekile kakhulu, ulwelo lunokuvuza; ukuba luqinile kakhulu, lunokonakalisa isiqu sevalvu okanye luthintele intshukumo.

4.2 Isisombululo

- Ukugcinwa kokupakisha: Jonga rhoqo kwaye utshintshe izinto zokupakisha ezigugileyo.

- Izinto ekufuneka ziqwalaselwe kubushushu: Khetha izinto zokupakisha ezifanelekileyo kubushushu benkqubo, njengezinto eziguquguqukayo zegrafiti ezisetyenziswa kubushushu obuphezulu.

- Ukulungiswa kwe-gland: Qinisa i-packing gland kwi-torque echazwe ngumvelisi, jonga ukuvuza emva kokulungiswa kwaye uphephe ukucinezelwa kakhulu.

---

5. Uxinzelelo okanye ubushushu obugqithisileyo

Xa iimeko zokusebenza zigqitha umda woyilo lwevalvu, ukuvuza kunokwenzeka, okuchaphazela izitywino zangaphakathi nezangaphandle.

5.1 Izizathu

- Uxinzelelo olugqithisileyo: Uxinzelelo oludlula umlinganiselo wevalvu lunokonakalisa isihlalo sevalvu okanye idiski, nto leyo eyenza kube nzima ukuyivala.

- Ukwanda kobushushu: Amaqondo obushushu aphezulu anokubangela ukuba izinto zande ngokungalinganiyo, nto leyo ebangela ukuguga kwetywina, ukuthamba okanye nokuba yi-carbonization, nto leyo enokuchaphazela ukulingana komphezulu wetywina, ikhulule itywina okanye ibangele ukuvuza kwangaphandle kwijoyinti.

- Ukungaqini kakuhle kwesikhumba: Phantsi kweemeko ezingaphantsi kwe--10 degrees, isitywino sinokuba buthathaka kwaye siqhekeke, nto leyo ebangela ukuvuza.

5.2 Izisombululo

- Uvavanyo olufanelekileyo loxinzelelo kunye nobushushu: Khetha iivalvu ezineqondo loxinzelelo kunye nobushushu ezidlula iimeko eziphezulu zenkqubo kwaye uqwalasele imida yokhuseleko.

- Ukunciphisa uxinzelelo: Faka ivalvu yokunciphisa uxinzelelo oluphezulu okanye isilawuli ukuthintela uxinzelelo olugqithisileyo.

- Ubushushu/ubushushu: Sebenzisa imikhono yobushushu okanye iintsalela zobushushu kwiindawo ezibandayo ukuthintela ukubanda.

5.3 Itheyibhile yokuthelekisa ubushushu bezinto ezibonakalayo

Apha ngezantsi kukho uluhlu lwemidiya kunye nobushushu obuhambelana nezitywino ezenziwe ngezinto ezahlukeneyo.

| IGAMA | ISICELO | UVAVANYO LWEXESHA ELIPHAKAMILEYO |

|---|---|---|

| I-EPDM | Amanzi, amanzi okusela, amanzi olwandle, iialcohols, iityuwa ze-organic ezinyibilikisiweyo, izisombululo ze-mineral acid, iziseko zeminerali ze-alkaline | -10℃ ukuya kwi-110℃ |

| I-NBR | Iioyile zeminerali nemifuno, igesi, iihydrocarbons ezingeyovumba, amafutha ezilwanyana, amafutha emifuno, umoya | -10℃ ukuya kwi-80℃ |

| I-VITON | Ii-asidi, amafutha, ii-hydrocarbon, iioyile zemifuno kunye neeminerali, amafutha | -15℃ ukuya kwi-180℃ |

| Irabha yendalo | Iityuwa, i-hydrochloric acid, izisombululo zokugquma zesinyithi, i-chlorine emanzi. | -10℃ ukuya kwi-70℃ |

| Irabha yeSilicon | Ukumelana nobushushu obuphantsi nobushushu obuphezulu, iiHydrocarbons zodidi lokutya, ii-asidi, iziseko, iiarhente zomoya | -10℃ ukuya kwi-160℃ |

| PU | ukusetyenziswa kweekhemikhali okungenabundlobongela njengamanzi, amanzi amdaka kunye namanzi olwandle | -29℃ ukuya kwi-80℃ |

| I-HNBR | Amanzi, Amanzi okusela, Amanzi amdaka. | -53℃ ukuya kwi-130℃ |

| IHypalon | Ukunyibilika kwe-asidi yeminerali, ii-asidi ze-organic kunye ne-inorganic, izinto ezi-oxidizing, | -10℃ ukuya kwi-80℃ |

| I-PTFE | amanzi, ioyile, umphunga, umoya, izinto ezimdaka, kunye nolwelo olubolayo | -30℃ ukuya kwi-130℃ |

| I-SS+Graphite | Iindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu, ezifana neenkqubo zomphunga, amashishini eekhemikhali kunye nepetroleum. | -200°C ukuya kwi-550℃ |

| I-SS+Stelite | yonke into ephakathi | -200°C ukuya kuma-600°C |

---

6. Ukususwa kwesikhumba kunye nokugqwala

6.1 Yintoni i-cavitation

Ukuqhekeka kwemithambo yegazi kubangelwa kukwehla ngequbuliso koxinzelelo lwe-liquid medium ukuya kuxinzelelo lomphunga wolwelo kwindawo ethontsizayo yevalvu (njengaphakathi kweplate yebhabhathane kunye nesihlalo sevalvu), okubangela ukuba ulwelo lujiye kwindawo ethile ukuze lwenze amaqamza. Xa la maqamza esiya kwindawo enoxinzelelo oluphezulu kunye nolwelo, ayawa ngokukhawuleza, avelise amaza oxinzelelo kunye nee-microjets, ezithi ke zona zibangele ukukhukuliseka kunye nomonakalo kumphezulu wokuvala ivalvu, isihlalo sevalvu kunye nomzimba wevalvu.

Nangona ukubola kunye nokubola zizinto eziphambili ezibangela ukusebenza kakuhle, kunokubangela ukuvuza ngokungathanga ngqo ngokonakalisa umphezulu wokuvala.

6.2 Yintoni ukugqwala?

Ukubola kubangelwa ziimpendulo zeekhemikhali okanye ze-electrochemical kumphezulu we-valve yebhabhathane ngenxa yokuxinana ixesha elide ne-corrosive media (ezifana ne-asidi, i-alkali, isisombululo setyuwa okanye umphunga oshushu kakhulu), nto leyo ebangela umonakalo kumphezulu wokutywina ivalve, isiqu sevalve, isihlalo sevalve okanye umzimba wevalve.

6.3 Izizathu

- Ukwehla koxinzelelo oluphezulu: Utshintsho olukhawulezileyo loxinzelelo luya kuvelisa amaqamza aqhumayo, aza kutshabalalisa idiski yevalvu okanye isihlalo sevalvu.

- Ukuhamba komhlwa: Le medium iqulethe ii-asidi, ii-alkali, iityuwa, njl.njl., ezisabela ngokuthe ngqo kumphezulu wesinyithi, nto leyo ebangela ukuba umphezulu wokutywina kunye nomzimba wevalvu unyibilike kancinci okanye ubole kwaye unciphe.

- Imidiya erhabaxa: Ulwelo olukhawulezayo oluqulethe amasuntswana luya kuguga umphetho wokutywina ngokuhamba kwexesha.

6.4 Izisombululo

- Ulawulo lokuhamba kwamanzi: Misela ubungakanani bevalvu ngokuchanekileyo ukuze unciphise ukuhla koxinzelelo kwaye usebenzise ubalo lwe-flow coefficient (Cv) ukuhlangabezana neemfuno zenkqubo.

- Ukuphuculwa kwezinto: Khetha izinto ezimelana nokugqwala ezifana nentsimbi engagqwaliyo okanye izinto zokugquma eziqinileyo zeediski zeevalvu kunye nezihlalo zeevalvu.

- Uyilo lwenkqubo: Nciphisa izinga lokuhamba kwamanzi ngokunyusa ububanzi bombhobho okanye ukongeza isixhobo sokunciphisa uxinzelelo phezulu.

Itheyibhile yeXabiso leCV ye-6.5

| Ixabiso le-Cv- Flow Rate Coefficient DN50 ukuya kwi-DN1400 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ubungakanani(mm) | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° |

| 50 | 0.1 | 5 | 12 | 24 | 45 | 64 | 90 | 125 | 135 |

| 65 | 0.2 | 8 | 20 | 37 | 65 | 98 | 144 | 204 | 220 |

| 80 | 0.3 | 12 | 22 | 39 | 70 | 116 | 183 | 275 | 302 |

| 100 | 0.5 | 17 | 36 | 78 | 139 | 230 | 364 | 546 | 600 |

| 125 | 0.8 | 29 | 61 | 133 | 237 | 392 | 620 | 930 | 1022 |

| 150 | 2 | 45 | 95 | 205 | 366 | 605 | 958 | 1437 | 1579 |

| 200 | 3 | 89 | 188 | 408 | 727 | 1202 | 1903 | 2854 | 3136 |

| 250 | 4 | 151 | 320 | 694 | 1237 | 2047 | 3240 | 4859 | 5340 |

| 300 | 5 | 234 | 495 | 1072 | 1911 | 3162 | 5005 | 7507 | 8250 |

| 350 | 6 | 338 | 715 | 1549 | 2761 | 4568 | 7230 | 10844 | 11917 |

| 400 | 8 | 464 | 983 | 2130 | 3797 | 6282 | 9942 | 14913 | 16388 |

| 450 | 11 | 615 | 1302 | 2822 | 5028 | 8320 | 13168 | 19752 | 21705 |

| 500 | 14 | 791 | 1674 | 3628 | 6465 | 10698 | 16931 | 25396 | 27908 |

| 600 | 22 | 1222 | 2587 | 5605 | 9989 | 16528 | 26157 | 39236 | 43116 |

| 700 | 36 | 1813 | 3639 | 6636 | 10000 | 14949 | 22769 | 34898 | 49500 |

| 800 | 45 | 2387 | 4791 | 8736 | 13788 | 20613 | 31395 | 48117 | 68250 |

| 900 | 60 | 3021 | 6063 | 11055 | 17449 | 26086 | 39731 | 60895 | 86375 |

| 1000 | 84 | 4183 | 8395 | 15307 | 24159 | 36166 | 55084 | 84425 | 119750 |

| 1200 | 106 | 5370 | 10741 | 19641 | 30690 | 46065 | 70587 | 107568 | 153450 |

| 1400 | 174 | 8585 | 17171 | 31398 | 49060 | 73590 | 112838 | 171710 | 245300 |

---

7. Iziphene kwiMveliso

Ngamanye amaxesha, ukuvuza kuvela kwiziphene ekwakhiweni kweevalvu ezinokubonwa ngexesha lokusetyenziswa okanye uvavanyo lokuqala.

7.1 Izizathu

- Iziphene zokuphosa: Ukuqhekeka okanye ukuqhekeka emzimbeni wevalvu kunokubangela ukuvuza kwangaphandle.

- Iingxaki zokutywina umphezulu: Ukungalungiswa kwediski okanye isihlalo ngokungalinganiyo kunokuthintela ukutywinwa okufanelekileyo, okubangela ukuvuza kwangaphakathi.

- Iimpazamo zokuhlanganisa: Ukufakwa okungafanelekanga kwezitywino okanye ukungalungelelani kakuhle kwezinto ngexesha lokwenziwa kunokubangela ukuvuza.

7.2 Izisombululo

- Uqinisekiso lomgangatho: Thenga kubavelisi abaziwayo abaneziqinisekiso ezifana ne-ISO 9001, kwaye ucele ingxelo yovavanyo loxinzelelo (umz., ngokwe-API 598) ukuqinisekisa ukuba akukho monakalo uvuzayo.

- Uvavanyo lwangaphambi kokufakwa: Yenza uvavanyo lokuvuza kwamanzi okanye umoya ngaphambi kokufakwa ukuze kufunyanwe iziphene, kwaye ubuyisele iiyunithi ezineziphene kumthengisi.

- Amabango ewaranti: Qinisekisa ukuba ivalvu iza newaranti egubungela iziphene zokwenza ukuze ikwazi ukutshintshwa ukuba ukuvuza kufunyenwe kwangethuba.

---

8. Isiphelo

Ivalvu yebhabhathaneukuvuza, ukusombulula ezi ngxaki kufuna indibaniselwano yokukhetha ivalvu efanelekileyo, ukufakelwa ngononophelo, ukugcinwa rhoqo, kunye nokwenza ngcono inkqubo. Ngokukhetha izixhobo ezifanelekileyo kwisicelo, ukulandela izikhokelo zokufakela kunye nokubeka esweni iimeko zokusebenza, abasebenzisi banokunciphisa kakhulu umngcipheko wokuvuza.

Ukuvuza kwevalvu yebhabhathaneIingxaki zinokubangelwa zizinto ezahlukeneyo, kwaye kufuneka izisombululo ezahlukeneyo kwiintlobo ezahlukeneyo zokuvuza. Nokuba kukuvuza kwangaphakathi okanye ukuvuza kwangaphandle, oku kunokuthiwa kubangelwa zizitywino ezigugileyo, iimpazamo zokufakela, ukuphazamiseka kwediski yevalvu, iingxaki zokupakisha isiqu sevalvu, uxinzelelo/ubushushu obugqithisileyo, iziphene zokwenza okanye ukugqwala. Umngcipheko wokuvuza kweevalvu zebhabhathane unokunciphisa ngempumelelo ngokukhetha ngokufanelekileyo, ukufakelwa ngokuchanekileyo, ukugcinwa rhoqo kunye nokusebenza kakuhle. Kwizicelo ezibalulekileyo, ukubonisana nabavelisi beevalvu okanye iinjineli zenkqubo kunokuqinisekisa ngakumbi ukusebenza okungenakuvuza kwaye kuphucule ukhuseleko lwenkqubo kunye nokusebenza kakuhle.